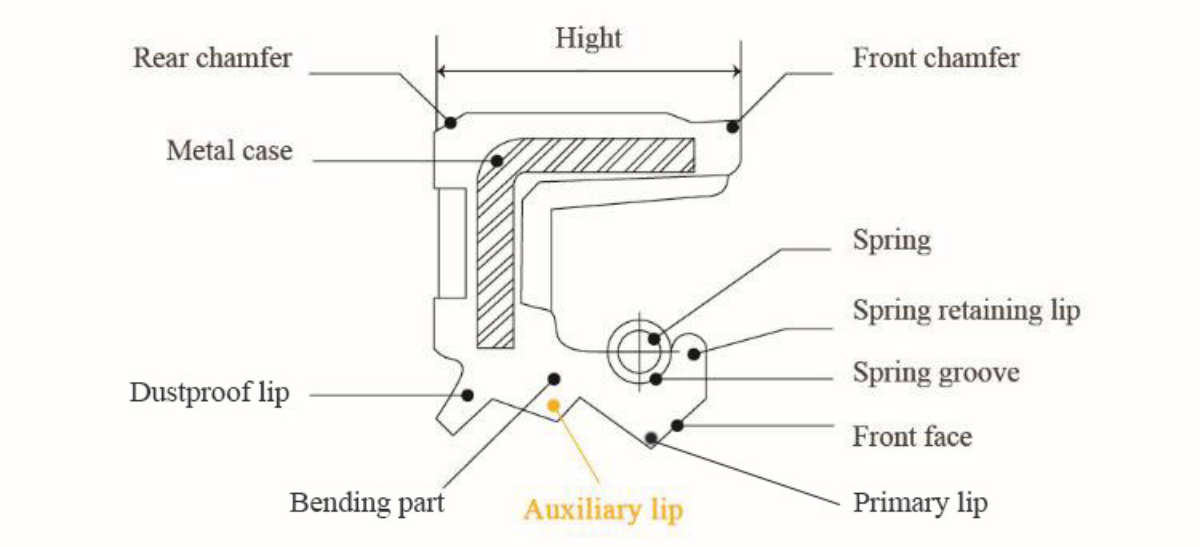

Although Oil Seals exhibit diverse styles, they fundamentally share a common construction: a flexible rubber lip securely bonded to a sturdy metal casing. Additionally, many incorporate a third crucial element – a garter spring – which is skillfully integrated into the rubber lip, ensuring both initial and long-term sealing efficiency. The overall radial sealing force of the lip arises from the synergy of the rubber’s pre-tension and the tensile force of the spring. Depending on the application, the sealing lip can be precision-cut on a lathe or pre-molded, often incorporating hydrodynamic features that aid in sealing under extreme conditions. The metal case may either be exposed or coated with rubber for enhanced assembly convenience or improved static sealing performance.

Spedent Sealing Solutions, leveraging its extensive experience across numerous application domains, offers cutting-edge Oil Seal design standards that are unparalleled in the industry.

Contact us to learn more.

Post time: Mar-29-2024